Search here to choose from a wide range of courses and programmes offered in our nation-wide campuses

JUGNU UBEROI

Industrialist

Christ University

Bachelor of Commerce (BCom)

1972

Ravi S

Indian Police Service

Christ University

PCMB (Christ College)

1996

P N Krishna Kumar

Wing Commander

Indian Armed Forces

Christ University

Bachelor of Commerce (BCom)

1993

B G Jagadeesh

Brigadier

Indian Armed Forces

Christ University

BSc PCM

1983

Syed Asad Abbas

National Television Media Personality

Christ University

MS Communication

2011

HARESH THARANI

Bachelor of Commerce (BCom)

(1982)

Chairman & CEO

Tharanco Group

NUPUR RASHI PANNA

BSc CME

(2006)

IAS

Indian Administrative Service

ABDULLAH RASHEED

Bachelor of Education

(2011)

Principal

Huravee School

Ministry of Education Republic of Maldives

VISWAKUMAR MENON

BA JPEnglish

(1995)

Associate Director Global Head of PR & Media Relations

Tata Communications

KURUVILLA CHERIAN

Bachelor of Commerce (BCom)

(2005)

Executive Director

EY

YATEESH BEGOORE

Legal Officer

Organisation for the Prohibition of Chemical Weapons (OPCW)

The Hague

GAUTHAM KARTHIK

BA Communication and Media, English and Psychology (CEP)

(2012)

Indian Actor

Film Industry

ANDREW CHAKRABORTY

Lawyer

Bradley Allen Love Lawyers, Canberra, Australia

AVINASH KAPOLI

Bachelor of Hotel Management (2004-08)

Trade Ambassador

Bacardi India Pvt. Ltd.

SUDHIR UNNIKRISHNAN

Bachelor of Commerce (BCom)

(1989)

SVP and Managing Director (India)

Blume Global

MALLIKHARJUNA RVR

Department of Computer Science MCA

(2001)

Head Of Mobile Technology

Axis Bank

SHWETA SASTRI

Bachelor of Business Management (BBM)

(2004)

Managing Director

Canadian International School Bangalore

MADONNA SEBASTIAN

Bachelor of Commerce Tourism

(2013)

Indian Actress

Tamil/Malayalam

BRUCE LEE MANI

BA JPEnglish

(1998)

Musician

Director, Taaqademy

SANJAY SHAND

Bachelor of Commerce (BCom)

(1989)

Managing Director

Shand Group of Industries

AJITH NAYAR

Bachelor of Hotel Management (1992 - 95)

Co Founder & CMO,

Camcom

BABU C JOSEPH

BSc PCM

(1987)

Chairman and Managing Director

White Group

KRISHNA BYRE GOWDA

Bachelor of Business Management (BBM)

(1994)

Politician

MLA, Byatarayanapura Constituency, Bangalore

BHUVAN G M

Bachelor of Hotel Management (1991 - 94)

Professor & Principal,

Apeejay Institute of Hospitality, Navi Mumbai

SRUTHI HARIHARAN

Bachelor of Business Management (BBM)

(2009)

Indian Actress / Producer (Kannada)

Film Industry

SAMYUKTA HORNAD

BA Communication and Media, English and Psychology (CEP)

(2012)

Indian Actress / Model (Kannada)

Film Industry

YOGESH BHAT

Bachelor of Business Management (BBM)

(1995)

Senior Vice President

Masai School

GAURAV SAIT

Master in Business Administration (MBA)

(2008)

Vice President

JP Morgan

_20230321123703..png)

AMULYA K G

Bachelor of Business Management (BBM)

(2009)

Indian Defence Accounts Service

Deputy Controller Defence Accounts, MEG (Madras Engineering Group) & Centre Bangalore

NIRANJAN NARAYANASWAMY

BA JPEnglish

(2007)

Executive Editor - News

Republic TV

DHANYA SKARIACHAN

BA JPEnglish

(2006)

Business Editor

Deccan Herald

MOHAMMED ZAHRIN BIN AZIZ

Bachelor of Hotel Management (BHM)

(2014)

Restauranteur

Director, Empire Group of Restaurants

PARINIKA PAVAN RAM

Bachelor of Commerce (BCom)

(2016)

KAS

Karnataka Administratice Service (KAS)

RAJEEV RAVINDRANATHAN

Bachelor of Business Management (BBM)

(1997)

Indian Actor

Film Industry

KETAN PISHE

Bachelor of Business Management (BBM)

(2001)

Partner

P N RAO FINE SUITS

GEORGE POTHAN POOTHICOTE

Bachelor of Commerce (BCom)

(2007)

Advocate, Supreme Court of India

Legal Consultant, Ministry of External Affairs

JOSE THOMAS

Bachelor of Hotel Management (BHM)

(1999)

Exective Chef

Taj Hotels Resorts and Palaces

MADHUKESHWAR DESAI

BA LLB

(2011)

Politician and Lawyer

National Vice President, Bharatiya Janata Yuva Morcha

SHILPI NEHA TIRKEY

Bachelor of Business Administrtaion (BBA)

(2010)

Politician

Member of Legislative Assembly Mandar Constituency

CHAITANYA K M

BA Communication and Media, English and Psychology (CEP)

(1994)

Film Director

Documentary Maker and Theater Person

SHILPA NAG

Master of Business Administration (MBA)

(2009)

IAS

Indian Administrative Service

LUCAS THOMAS

Master of Computer Applications (MCA)

(2000)

Senior Vice President

Bank of America

JOEL T V

BCom

(2011)

Vice President

Goldman Sachs

SAMI FAIZULLAH

BCom

(2014)

Senior Vice President

Bank of America

FOUZIA TARANUM

PGDM

Indian Administrative Service (IAS)

K FRANCIS GEORGE

Politican

Ex-Member of Parliament,

Lok Sabha

M N REDDI

Indian Police Service (IPS)

Former Commissioner of Police

Bangalore City

C B RISHYANTH

BCom

Indian Police Service (IPS)

SRIRAM SULIA

(2009)

Radio Jockey

Head of Programming

FEVER FM & RADIO ONE

PUNEET KOTHAPA

BCom

President

The Narayana Group

_20230321044343..png)

SUPRIYA LOHITH

BSc CMS

(2006)

Playback Singer

South Indian Films

SRINATH SATHYANARAYANA

MCA

(1999)

Chief Technology Officer

Fincare

TRISHIKA KUMARI WADIYAR

MA Economics

Maharani of Mysore and

Wife of Yaduveer Krishnadatta Chamaraja Wadiyar

27th Maharaja (King) of Mysore

MADAN KUMAR

MCA

(2004)

Managing Director

Accenture's Advanced Technology Centers in India

NEHA CADABAM

MSc Psychology

(2010)

Psychologist

Executive Director

Cadabams Group

KARAN MACHADO

BA CEP

(2014)

Radio Jockey

94.3 Radio One

MONICA JAIN

BA Economics Honours

(2016)

Climate Change Consultant

The World Bank

POOJA CHHABRIA

BA CEP

(2012)

Digital Editor

World Economic Forum

RUBEN RAJAMANICKAM

(2001)

Senior Vice President

JP Morgan Chase & Co

KALMESHWAR SHINGENAVAR

MBA

(2006)

Indian Police Service (IPS)

PRADEEP JOHN

BA HEP

(1999)

Second in Command

Central Reserve Police Force

Chennai

ANIRUDH R GANGAVARAM

BBA

(2018)

Indian Revenue Service

CHOCKO VALLIAPPA

BCom

(1988)

CEO, Vee Technologies

Vice Chairman, Sona Group of Instituions

ANTHONY HUANG

BHM

Executive Chef

Sheraton Grand Bangalore

NEHA CADABAM

BA (Psychology, Communicative English, Literature)

MSc Clinical Psychology

2005 - 2010

Executive Director, Cadabams Group

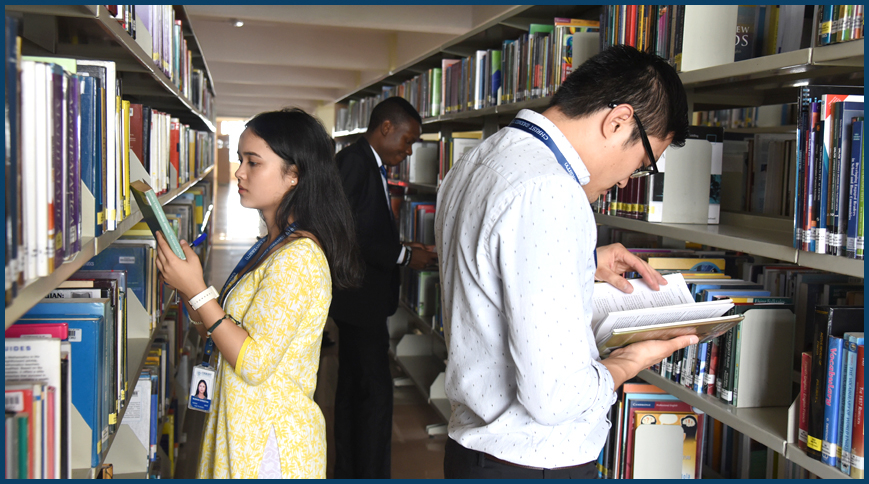

A well-equipped infrastructure to promote the academic and cultural activities of CHRIST is one of our primary accomplishments. An attempt to provide equal opportunity for each and every Christite is the idea behind this unique feature of our campus.

Countries

Academic Departments

International Students

Library Books

Alumni

Dharmaram College Post, Hosur Road, Bengaluru - 560029,

Karnataka, India

Tel: +91 804012 9100 / 9600

Fax: 40129000

Email: mail@christuniversity.in

Web: http://www. christuniversity.in

EXCELLENCE AND SERVICE

CHRIST (Deemed to be University) is a nurturing ground for an individual's holistic development to make effective contribution to the society in a dynamic environment.